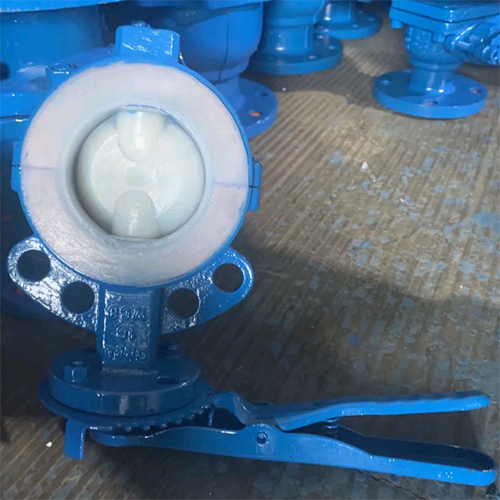

Best Silent Check Valve For Sump Pump Manufacturer – Fluorine-lined stainless steel/cast steel national standard butterfly valve – JUGAO VALVE Detail:

Product Description

1: ISO5211 top flange together with stem square suitable for direct mounting of actuators

2: Stem anti-blowout design keep safety in field use

3: Dirtscraper prevents moisture penetrating into the shaft area

4: Multi-standard alignment holes suitable for various standard of flanges of EN1092 PN10, PN16, ASME B16.5 CLASS150, JIS B2239 10K, 16K, BS 10 Table D, Table E

5: Suitable for high pressure and full vacuum service due to the use of a cartridge seat design

6: No exposed pins or bolts for stem-to-disc connection

7: No need for flange gaskets

8: No risk of damage to the valve during installation in closed position

9: Bubble-tight shut of at full pressure rating

10: Large flow capacity and enough strength because of streamline disc design

11: Plug with O-ring sealing eliminates any leakage from the stem

Product features

PARTS LIST AND MATERIAL SPECIFICATION

| NO. | Part name | Material |

| 1 | Body | ASTM A536 65-45-12, WCB, CF8M |

| 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| 3 | Seat | EPDM,NBR,FRM.PTFE |

| 4 | Stem | SS420,SS431 |

| 5 | Lower Stem | SS420,SS431 |

| 6 | Retalner | Nylon for DN50-DN300, SS304 for DN350-DN2000 |

| 7 | Bearing | RPTFE with Graphite on I.D. |

| 8 | Weather seal | NBR |

| 9 | Nuts | Stainless steel |

| 10 | Plug | Steel galvanized for DN50-DN300, Cover plate for DN350-DN2000 material same as body with SS304 bolts |

| 11 | Screw | SS304 |

TECHNICAL DATA

| Body style | wafer | ||||||||||||

| Nominal diameter | 2″ – 80″ (DN50mm – DN2000mm) | ||||||||||||

| center flange | ISO5211 | ||||||||||||

| Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2000 | ||||||||||||

| Temperature range | -20 °C to + 140 °C (depending on pressure, medium and material) | ||||||||||||

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

||||||||||||

| Applications | Potable Water, Wastewater, Seawater, HVAC | ||||||||||||

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator | ||||||||||||

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | ||

| DN | INCH | ||||||||||||

| 50 | 2″ | 126 | 78 | 13.5 | 94.3 | 9 | 50 | 8 | 70 | 31 | 43 | 2 | |

| 65 | 2 1/2″ | 134 | 84 | 13.5 | 107.6 | 9 | 50 | 8 | 70 | 45 | 46 | 2.5 | |

| 80 | 3″ | 138 | 92 | 13.5 | 123.9 | 9 | 50 | 8 | 70 | 64 | 46 | 3 | |

| 100 | 4″ | 167 | 114 | 13.5 | 157 | 11 | 70 | 10 | 90 | 91 | 52 | 4.5 | |

| 125 | 5″ | 180 | 129 | 17.5 | 181.5 | 14 | 70 | 10 | 90 | 110 | 56 | 6 | |

| 150 | 6″ | 203 | 144 | 17.5 | 212 | 14 | 70 | 10 | 90 | 146 | 56 | 7 | |

| 200 | 8″ | 228 | 179 | 24.5 | 267.4 | 17 | 102 | 12 | 125 | 193 | 60 | 12 | |

| 250 | 10″ | 266 | 216 | 25 | 323.6 | 22 | 102 | 12 | 125 | 241 | 68 | 17 | |

| 300 | 12″ | 291 | 247 | 25 | 377.4 | 22 | 102 | 12 | 125 | 292 | 78 | 25 | |

| 350 | 14″ | 332 | 273 | 30 | 425 | 27 | 125 | 14 | 150 | 329 | 78 | 41 | |

| 400 | 16″ | 363 | 317 | 30 | 484 | 27 | 125 | 14 | 150 | 376 | 102 | 58 | |

| 450 | 18″ | 397 | 348 | 39 | 537 | 36 | 140 | 18 | 175 | 425 | 114 | 80 | |

| 500 | 20″ | 425 | 393 | 39 | 589.5 | 36 | 140 | 18 | 175 | 475 | 127 | 97 | |

| 600 | 24″ | 498 | 453 | 49 | 693.1 | 46 | 165 | 22 | 210 | 573 | 154 | 169 | |

| 700 | 28″ | 626 | 531 | 90 | 928 | 63.1 | 254 | 18 | 300 | 674 | 165 | 252 | |

| 750 | 30″ | 660 | 564 | 90 | 984 | 63.1 | 254 | 18 | 300 | 727 | 165 | 290 | |

| 800 | 32″ | 666 | 601 | 90 | 1061 | 63.1 | 254 | 18 | 300 | 771 | 190 | 367 | |

| 900 | 36″ | 722 | 660 | 110 | 1170 | 74.7 | 254 | 18 | 300 | 839 | 203 | 465 | |

| 1000 | 40″ | 806 | 728 | 120 | 1290 | 83.7 | 298 | 22 | 350 | 939 | 216 | 606 | |

| 1100 | 44″ | 826 | 771 | 140 | 1404 | 94.7 | 298 | 22 | 350 | 1036 | 255 | 805 | |

| 1200 | 48″ | 941 | 874 | 150 | 1511 | 104.7 | 298 | 22 | 350 | 1137 | 276 | 900 | |

| 1400 | 56″ | 1000 | 940 | 175 | 1685 | 139.9 | 356 | 32 | 415 | 1351 | 279 | 1158 | |

| 1600 | 64″ | 1155 | 1085 | 195 | 1930 | 160 | 356 | 32 | 415 | 1548 | 318 | 1684 | |

| 1800 | 72″ | 1200 | 1170 | 195 | 2170 | 174.5 | 406 | 39 | 475 | 1703 | 356 | 2645 | |

| 2000 | 80″ | 1363 | 1360 | 245 | 2345 | 199 | 406 | 39 | 475 | 1938 | 406 | 4000 | |

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Best Silent Check Valve For Sump Pump Manufacturer – Fluorine-lined stainless steel/cast steel national standard butterfly valve – JUGAO VALVE, The product will supply to all over the world, such as: Danish, Cyprus, Ecuador, We are proud to supply our products to every costumer all around the world with our flexible, fast efficient services and strictest quality control standard which has always approved and praised by customers.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.

-

OEM/ODM Manufacturer Butterfly Valve Germany -...

-

China wholesale Smolensky Check Valve Manufactu...

-

China wholesale Hot Water Heater Check Valve Ma...

-

China wholesale Flanged Wafer Check Valve Facto...

-

OEM/ODM Manufacturer Ball Valve 3 Pcs Body - F...

-

Factory Cheap Rollover Check Valve - Fluorine-...